|

Hong Kong Geoguide 1: Guide to Retaining Wall Design (2020 Edition)

3 Construction Considerations in Design

3.1 General

In the interest of safety and economy, designers of retaining walls should give careful consideration to methods of construction and materials to be used. This will help to avoid intrinsically risky designs and may result in significant economies, e.g., savings can often be achieved by incorporating part of the temporary works into the permanent structure.

3.2 Selection and Use of Backfill

3.2.1 General

The choice of materials for backfilling behind a retaining wall depends upon the materials available, the site conditions, the load to be placed on the backfill and the type of wall. The ideal backfill is a free-draining, durable material of high shear strength and stiffness, and which is free from any harmful matter. However, the final choice of materials often depends on the cost and availability of such materials balanced against the cost of providing more substantial support for lower-quality backfill materials.

Materials selected for use as backfill generally must not contain : (a) peat, vegetation, timber, organic or other degradable materials, (b) dangerous or toxic material or material susceptible to combustion, (c) metal, rubber, plastic or synthetic material, (d) material susceptible to significant volume change, e.g. marine mud, swelling clays and collapsible soils, or (e) soluble material.

Also, the backfill should not be chemically aggressive, e.g. the presence of excessive sulphate in soils can cause accelerated deterioration of concrete and steel (BSI, 1986a).

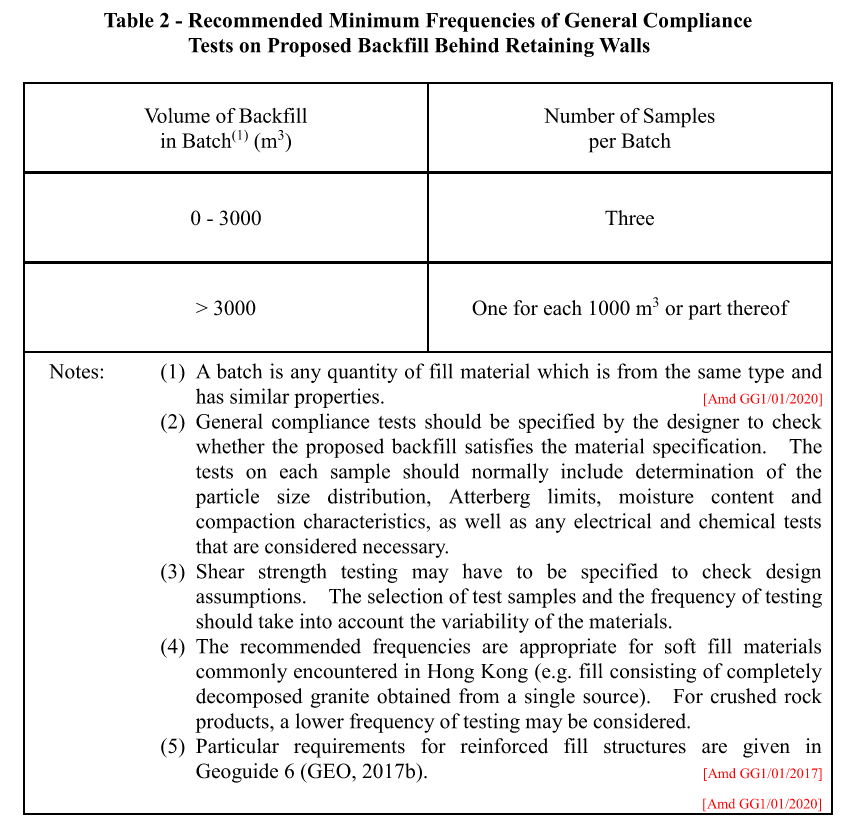

It should be demonstrated during the design stage or in the early stage of construction that the properties of the proposed source of backfill comply with the specification. The designer should specify the type, number and frequency of compliance tests, but there should be flexibility to allow the testing requirements to be increased during construction according to the heterogeneity of the material and the size of the retaining wall. Some minimum sampling frequencies are recommended in Table 2. Compliance testing of the proposed backfill should normally include determination of the particle size distribution, Atterberg limits, moisture content and compaction characteristics, as well as any electrical and chemical tests that are considered necessary. Shear strength testing may sometimes have to be specified to check the design assumptions.

Determination of insitu densities and moisture contents should be specified for compaction control. Table 3 gives recommended minimum frequencies of compaction control tests for backfill placed behind retaining walls.

Where the contractor provides the backfill, the cost of a backfilled retaining wall can be minimized if the contractor is allowed the widest choice of materials, particularly where suitable materials can be found in the vicinity of the works site. Therefore, the specification of backfill should not be too restrictive.

3.2.2 Types of Backfill

The use of clay backfills is not recommended because of problems associated with swelling, shrinkage and consolidation of clay.

Backfills composed of uniform silts should not be used, as these materials are very difficult to compact.

For backfills composed of fine soils, adequate drainage should be provided to prevent the build-up of water pressure (see Section 8.4). Free-draining granular materials usually do not warrant the same amount of attention in this respect but may still require protection by properly designed filters.

For a retaining wall, the movement required to produce the active state in cohesive materials with a significant clay content is much greater than that for granular materials. This, together with the fact that the former generally have lower shear strengths, means that the amount of shear strength mobilised for any given wall movement is considerably lower for cohesive materials than for granular materials. The corresponding earth pressure on the 'active' side for a particular wall movement is therefore higher if cohesive soil is used for the backfill.

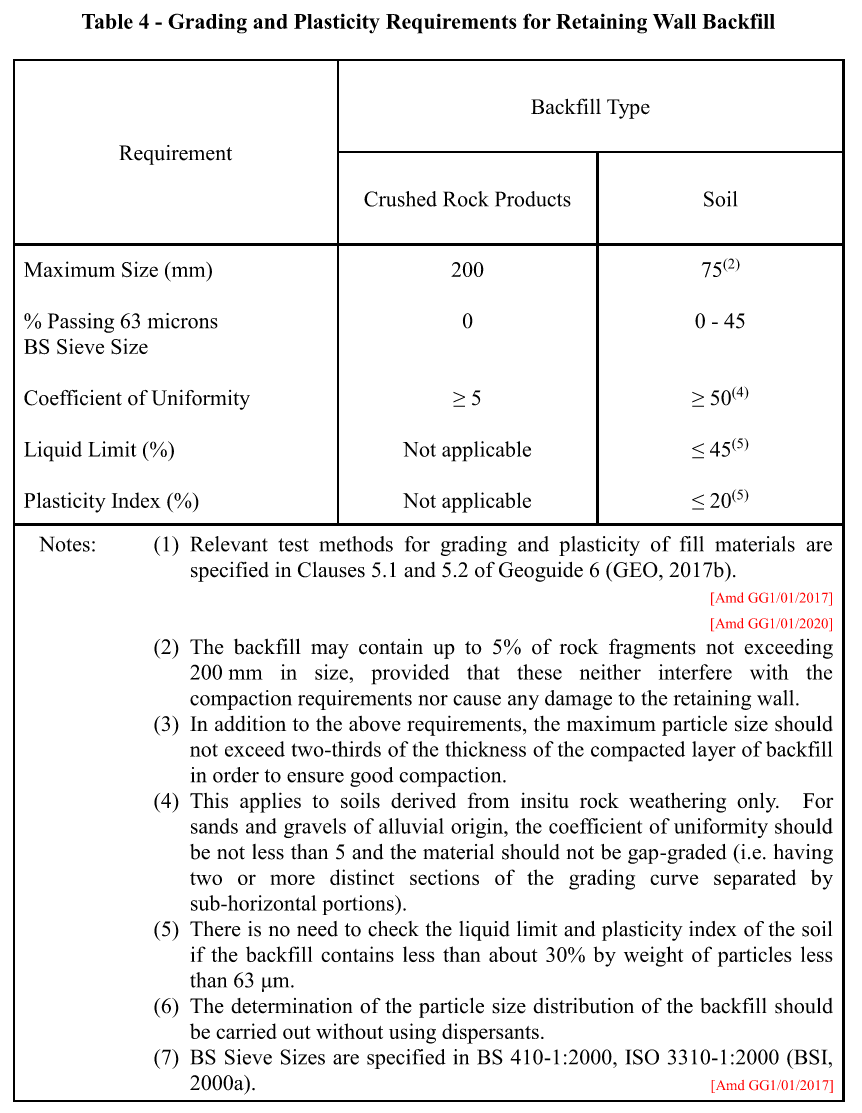

In Hong Kong, backfill for retaining walls customarily comprises selected soils derived from insitu weathering of granitic or volcanic (tuff and rhyolite) rocks (Figure 1). The sandy materials are suitable for backfill in most types of retaining walls, provided that they meet the requirements for soil backfill given in Table 4. Materials derived from weathered shales and mudstones and argillaceous facies within the volcanics and the meta-sediments of the Lok Ma Chau Formation may undergo considerable swelling by absorption of water and should not be used as retaining wall backfill.

Fill composed of crushed rock products is a very suitable material for use as backfill to retaining walls. Ideally, the rock fill should consist of pieces of hard, durable rock of which not more than 30% by weight is discoloured or shows other evidence of decomposition. It should be well-graded and have a maximum particle size of 200 mm (Table 4). Movement of retained soil due to migration of fines into the rock fill needs to be prevented, and this requires the provision of a properly designed filter between the soil and the rock fill (see Section 8.5).

Free-draining materials are required for filling gabion baskets and for the interior filling between units in a crib wall. Guidance on suitable infilling materials for crib walls

and gabions is given in Chapter 9.

Particular requirements for backfill are necessary for reinforced fill structures. Detailed specifications for fill for such structures are given in Geoguide 6 (GEO, 2017b).

|